Ironing Tables & Laundry presses

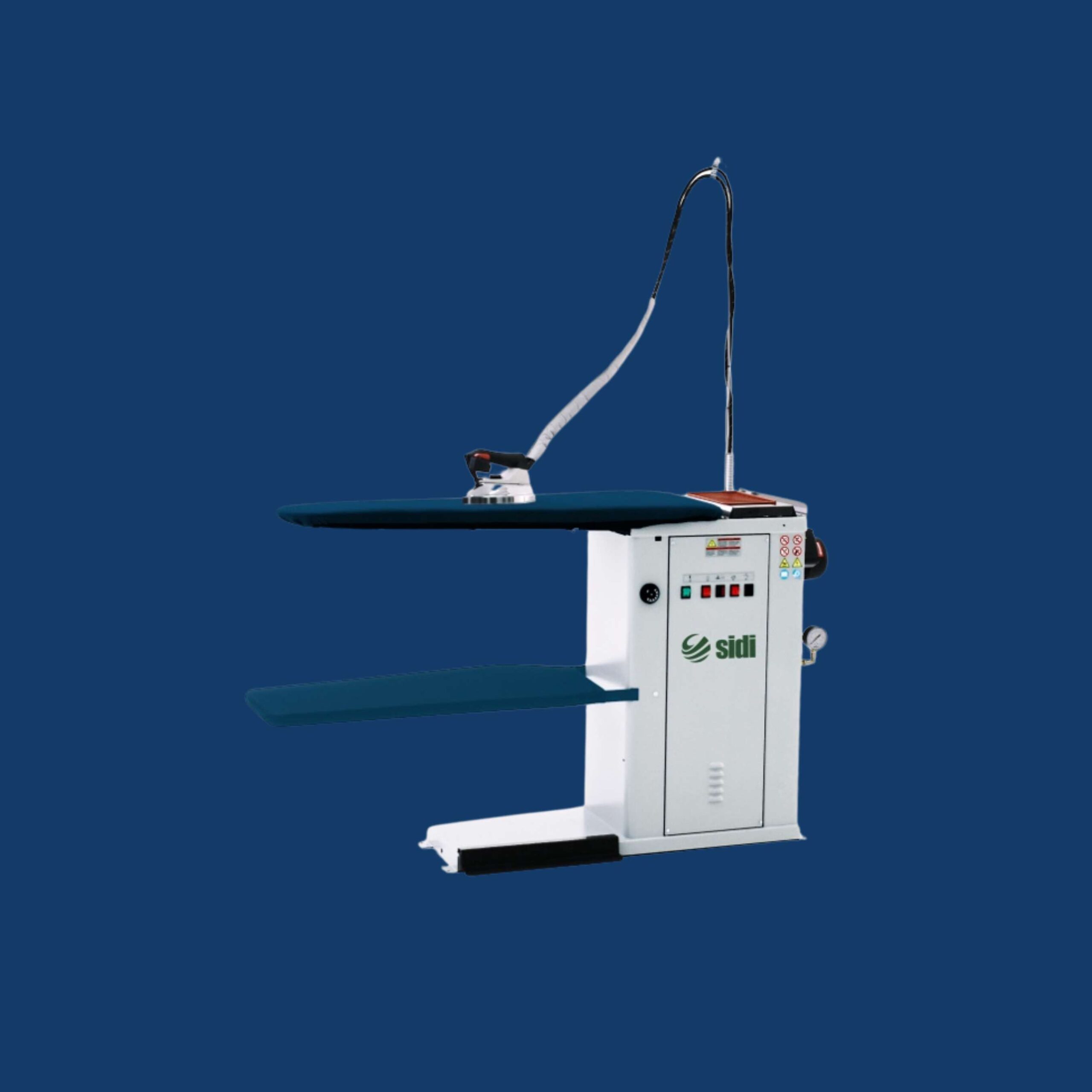

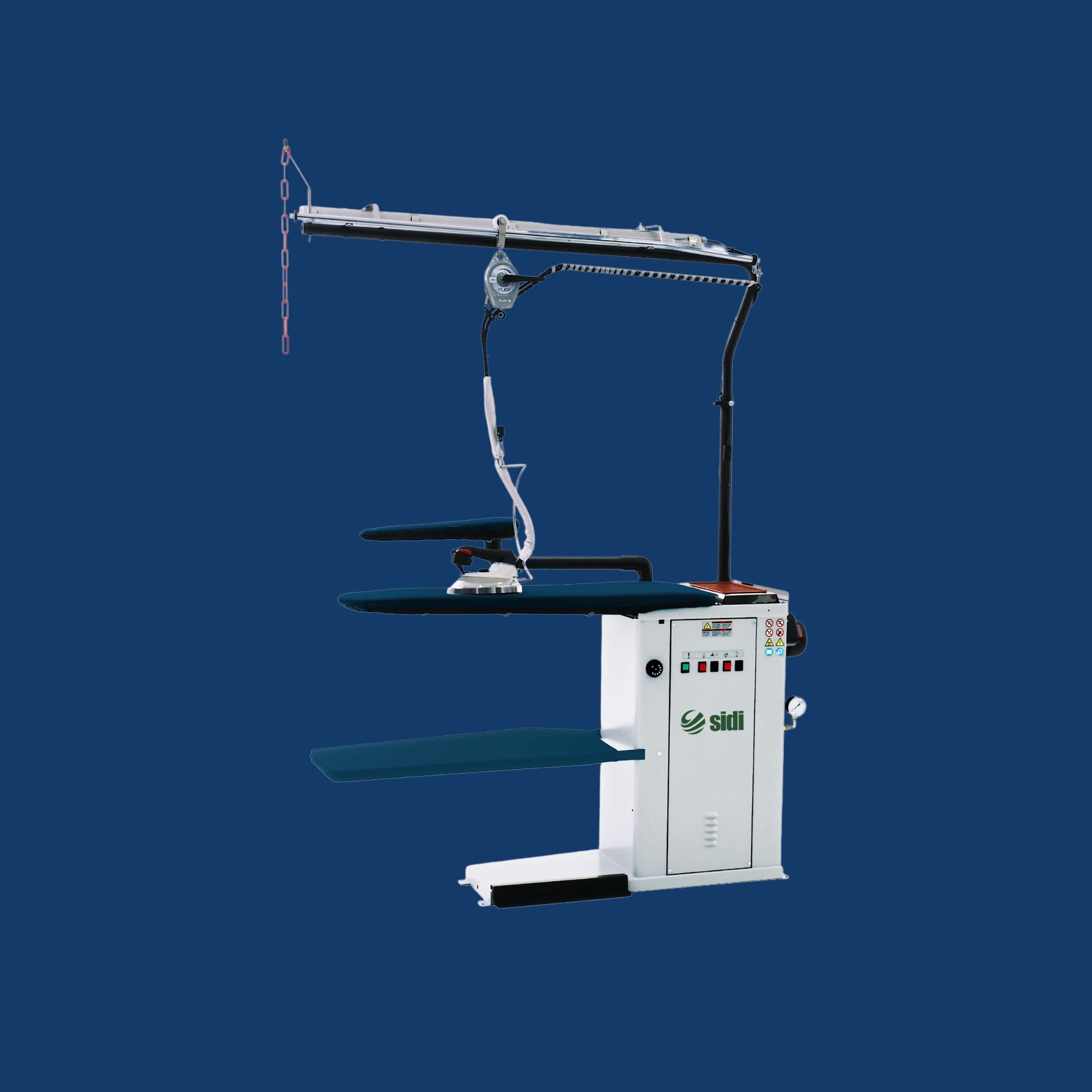

FVC Utility ironing tables

Buck size 1100×380 – small end 230 mm.

- Utility, VACUUM, ironing table, with thermostatically controlled electric heating.

- Standard features include5-liters automatic electric built-inboiler,3.3-kWheating elements,

- 2.8-bar working pressure, vacuum motor, electric-steam iron, 304-grade stainless steel iron rest.

- Voltage. 400-3+N-50 Hz.

OPTIONS :

- Pivoting arm with eithet sleeve-ironin shape or spotting shape

- Steam spotting gun

- Steam/air spotting gun or cold spotting gun for chemical agents

- Water spray gun with support

- Lighting group with or without pulley and iron suspension.

Rectangular Ironing table

Buck size 1300×650 mm.

- Rectangular,VACUUM,ironing table.

- Thermostatically controlled electric heating, height adjustment from 750 to 930 mm.

- Standard features include vacuum motor

- 304-grade stainless steel iron rest.

- Ready to fit 2 arms with shapes.

- Voltage. 230-1-50 Hz.

Dry Cleaning presses

Manual Utility Press

- Universal ironing press with manual functioning and very easy to use and maintain.

- The movement of the upper head is operated by a pressure pedal.

- Padded head with live steam or polished, lower buck with live steam and vacuum.

- Both bucks are steam heated.

- Available either self-contained or ready for connection to external steam and vacuum supplies.

- 20-lt automatic electric boiler with electronic control,

- 10- or 12-kW heating elements,

- 4.8-bar working pressure and pump.

- Voltage. 400-3+N-50 Hz.

Air Operated Utility Press

- Air operated universal press, with good performances and moderate price.

- Padded and live steam or nickel-plated polished head,

- lower buck with live steam and vacuum, blowing upon request. Adjustable squeezing pressure.

- Both bucks are steam heated.

- 50° head opening.

- Available either self-contained or ready for connection to external steam, vacuum and air supplies.

- The model with padded head is available in the following buck forms:

OPTIONS :

- 9 or 20 liters boiler with or without device for automatic HEATING of the bucks

- Blowing device on lower buck through a built-in vacuum

- Built-in compressor

- Steam iron assembly with steam electric iron or ALL STEAM with safety device

- Spotting gun

- Arm with shape

Form Finishers

The form finisher’s range M-781 has been engineered to meet the demand of blow finish for all outerwears in dry cleaning and laundry stores, the garment industry, ironing services and in the hospitality industry.

Features are: Finishing cycles controlled by microprocessor with 10 stored programs, manual cycle start or automatic cycle start using a foot pedal, adjustable hot air flow, revolving or fixed dummy if combined with the sleeve tensioning group.

Regular Form Finisher

OPTIONS :

- ”M-781/T” sleeve tensioning assembling specifically studied for the finishing of anoraks and jackets

- 9 or 20 liters boiler

- GFV group with steam iron

- steam gun

- water spray gun

- 1,7 HP fan

- special dummies as alternative to standard dummy

Multi Form Finisher

The tensioning form finishers M 501/M 502 have been designed to meet the needs of the WET cleaning system, that requires vertical tensioning for perfect seam finishing and fabric revitalising. This form is suitable for jackets, outerwear, leather wear, dresses and similar garments of any size and textures. M-501 is also suitable for dry cleaned garments, by allowing a very high quality finishing, limiting the number of touch-ups to very minor details and increasing productivity without the need of specialized labour. The high quality finishing is provided by the special garment tensioning and by the powerful hot air flow. The positioning of the dummy is automatic, thanks to a photocell. Cycles are adjustable, savable and managed by a plc with AF Logic interface. All formers of the M 501/M 502 series are ready for connection to external steam supply.

Shirt Finishers

Magic Pro

The MAGIC PRO has a wide range including men’s shirts, women’s blouses, polo shirts, medical uniforms, and chef’s uniforms. This machine drew on our many years of manufacturing experience and customer interaction to meet the ultimate goal of reducing energy consumption and machine size. It makes a state of the art shirt finisher affordable for every shirt laundry. The H.A.R.S. (Hot Air Recovery System), is an efficient system for the recapture of air from the. shoulder press. This device maintains a constant 150° air temperature and conveys the air through a special channel into the fan to speed the drying of the shirt, reducing energy consumption by 20 to 30%, with faster drying times and higher productivity. It is the only shirt finisher in the world pressing both the yoke and the tucks at the same time, with Teflon press heads to avoid marks on dark fabrics. Additional innovations include the front horizontal sliding paddle and a brand new adjustable cuff clamps system, with rotating rounded clamps. The PLC TOUCH SCREEN managing functions and finishing cycles, is adjustable and integrated in the main frame. For the operator’s convenience, the controls of the basic functions are repeated on the front paddle with customizable buttons. If connected through an Ethernet port, it is possible to control the Touch Technology even from remote locations. The “TOTAL ELECTRIC” version , in conjunction with the “totally electric” version of the collar and cuff press, allows the installation of a highly productive and professional shirt ironing system anywhere without the requirement for steam or water. The “TOTAL ELECTRIC” version also offers the opportunity to select the “ECO” or “PRO” operation according to different electrical powers available and production volumes.

Vega pro

VEGA PRO is the solution for the pressed finishing of shirts, polo shirts, chef’s and nurse’s jackets with rotary double-buck for maximum productivity and incomparable ironing quality. The innovative characteristics are:

- new dummy design with contoured Teflon-coated bucks that allows for a more precise and faster shirt positioning as well as flawless finishing of a wide range of shirt sizes;

- powerful 3HP fan which guarantees a faster drying of the shirt;

- wider hot air recapture system (H.A.R.S.) that allows a 20% reduction in steam consumption for a reduced blowing cycle time, and improved productivity;

The main features of VEGA PRO include:

- special rounded and rotary clamps with a Teflon-coated surface, assembled on the innovative “V-shaped” structure that guarantees stability and precision of movement.

- the hot air recapture system ensures a significant reduction in drying time, while decreasing energy consumption and temperature of the working environment.

- colour touch screen PLC for total machine control, also remotely via Ethernet connection. It allows to customise operational programmes, check productivity, access diagnostic features and maintenance alerts, as well as execute auto-tests and software updates;

- all pressing elements of this shirt finisher, which are in direct contact with the fabric, are Teflon-coated to prevent shine on dark fabrics.

VEGA PRO can also be used by a non-skilled operator, thanks to its perfect automation, achieving an hourly output of up to 120 shirts/hour.

Spotting Tables

Cold and Hot Spotting Table & Spotting Cabinet

Professional COLD and HOT spotting tables are ideal to remove any kind of stain in both the dry-cleaning and garment industries, for the treatment of stains deriving from different production stages. Available in two versions: F-793 – Cold spotting table. Features: Stainless steel board and sleeve spotting arm. Garment tray. Cooling coil. Two spotting guns and two tanks for liquid spotting agents. Air drying gun. Available with built-in vacuum unit or ready for connection to central vacuum supply.

Available options:

- Suction cap either ready for external exhaust or with activated carbons filter

- Built-in compressor

- Steam and air gun assembly.

S-782 – Hot spotting table. Features: Stainless steel board and sleeve spotting arm. Steam available in three different options: dry, wet and a mix of steam and water. Vacuum is concentrated on both the nose of the board and the swinging sleeve shape and it quickens the drying phase and keeps moistened areas from spreading. Ready for connection to central vacuum or with built-in vacuum upon request. This cabinet is the ideal solution to improve the quality of your dry-cleaning This compact and functional unit (100×85 cm) offers in a reduced space both pre and post -spotting facilities. EKO is built from high grade stainless steel and meets the modern requirements for protection of the environment thanks to the built-in powerful suction fan and ecological active carbon filtration set. Pre-spotting unit includes: one 5 liter pressurized soap tank, stainless steel, with soap spray gun. Post-spotting unit includes: two independent pivoting stainless steel spotting bucks

cold spotting gun with tank and support. Air drying gun.

OPTIONS :

- Steam/Air gun.

- Automatic electronic steam boiler.

- Soap tank with spray soap guns.

- Cold spotting gun

Steam Generator

Cold and Hot Spotting Table & Spotting Cabinet

The BR 8-16 SERIES are steam generators with electronic control: the special design allows for a quick and easy installation with the added benefit of all components being easily accessible, routine maintenance to be straightforward and simple. These steam boilers are constructed from high grade materials and conform to CE European Standards.

They are produced in the following models:

- BR 8, steam production 9 kg/hour, 5-lt boiler, steam solenoid valve and water pump included

- BR16, steam production from 9 kg to 16 kg/hour, 9-lt boiler, steam solenoid valve and water pump included

Model BR 16 is also available in DELUXE version, recommended for intensive use, with 9 lt. boiler. In this model components like pressure switch, safety valve, probes and water solenoid valve and electric cables have been enhanced to better support high work volumes.

Electric steam generators with ball-cock water level control. The electric steam generators of the BR-INOX series, with body of boiler entirely made of STAINLESS STEEL AISI 304, are produced in accordance to the PED regulations. The steam generator can be fed directly by the water supply network or by a special steel tank.

The BR-INOX series is available with boilers of different sizes and different power:

- BR-INOX 16, boiler volume 16 lts and stainless steel electric heating elements of 7-8-10-12-15 Kw

- BR-INOX 24, boiler volume 25 lts and stainless steel electric heating elements of 6-7-8-10-12-14-15-16-18-20-22 kW, with a unique group of heating elements or two groups.

- BR-INOX 60, boiler volume 55 lts and stainless steel electric heating elements of 20-24-30-36-40-50- 60 kW, with two groups of heating elements.

- BR-INOX 120, composed by two overlapping BR-INOX 60 boilers which can be used at the same time.

- BR-INOX 180, composed by three overlapping BR-INOX 60 boilers which can be used at the same time.

OPTIONS

- stainless steel tank for water feeding and condensate recovery

- all tank components in contact with water made in stainless steel.