Washer Extractors

Washer Extractor

Capacity :11,14,18,22 kgs

- Grey skin plate outer casing.

- AISI 304 stainless steel drum

- EASY TOUCH 2 microprocessor control with 7” touch screen.

- 20 pre-set programs, fully programmable.

- 8 signals for dosing pumps.

- 3 water inlets.

Washer Extractor

Capacity : 28kgs

- Grey skin plate outer casing.

- AISI 304 stainless steel drum

- EASY TOUCH 2 microprocessor control with 7” touch screen.

- 20 pre-set programs, fully programmable.

- 8 signals for dosing pumps.

- 3 water inlets

Washer Extractor

Capacity : 35, 45kgs

- Grey skin plate outer casing.

- AISI 304 stainless steel drum

- EASY TOUCH 2 microprocessor control with 7” touch screen.

- 20 pre-set programs, fully programmable.

- 8 signals for dosing pumps.

- 3 water inlets

Washer Extractor

Capacity : 60, 80kgs

- Grey skin plate outer casing.

- AISI 304 stainless steel drum

- EASY TOUCH 2 microprocessor control with 7” touch screen.

- 20 pre-set programs, fully programmable.

- 8 signals for dosing pumps.

- 3 water inlets

Washer Extractor

Capacity : 100, 120kgs

- Grey skin plate outer casing.

- AISI 304 stainless steel drum

- EASY TOUCH 2 microprocessor control with 7” touch screen.

- 20 pre-set programs, fully programmable.

- 8 signals for dosing pumps.

- 3 water inlets

High spin washer extractor-Soft mounted.

Capacity : 8, 10 kg

- Grey skinplate outer casing.

- AISI 304 stainless steel drum and vat.

- Extraction speed 1.250 RPM.

- EASY TOUCH 2 microprocessor control with 4.3” touch screen, 20 presetprograms,fully programmable.

- Danube Online communication standard – free and easy IoT connection

- Detergents box with 4 compartments.

- 8 signals for dosing pumps.

- 2 water inlets (hot and cold).

- Model with drain valve and model with drain pump.

- Leveling feet included.

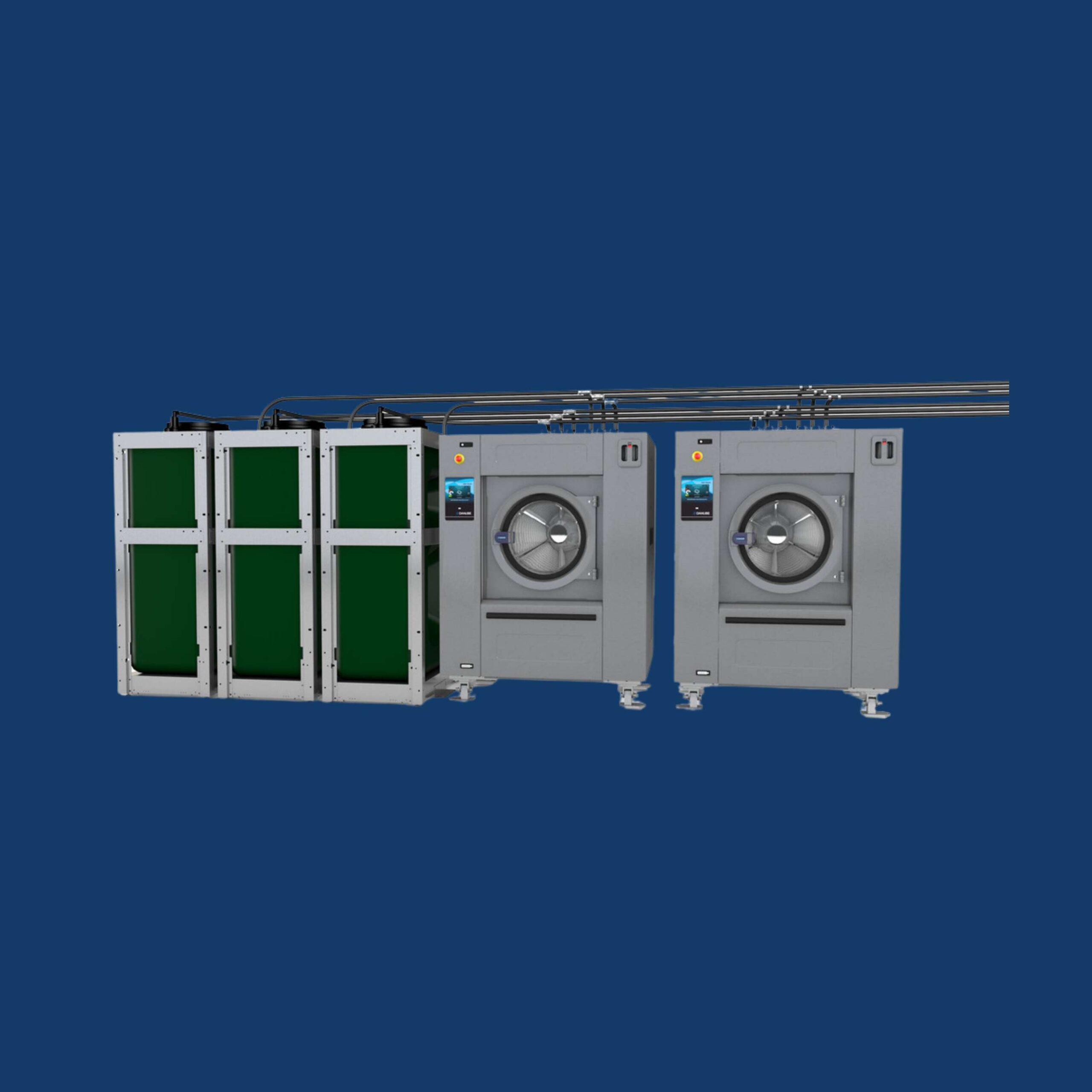

Barrier Washers

BECAUSE HYGIENE MUST ALWAYS BE an ABSOLUTE PRIORITY

How to avoid cross contamination in hospitals, clean rooms, nursing homes, healthcare centres… The solution exists with barrier washers: they provide the perfect solution to prevent cross contamination between soiled and clean linen in laundries (180° opposite double doors, RABC compliance).

Our range of DBW barrier washers is available from 27 to 70 kg. Equipped with the new EASY TOUCH 2 (ET2) microprocessor with wide touch screen, fully programmable, this range offers as standard many features such as connectivity, Wet Cleaning or traceability which are particularly appreciated in healthcare sector. Our MEDICAL range comes with capacities 16 and 22 kg and is also equipped with the ET2 control as well as our Pullman AS100 model.

Barrier Washer

Capacity :16-22 kgs

- Pass through barrier washer extractors, soft mounted,

- G factor 350, extraction speed 1000 RPM.

- Easy installation, no need for anchoring.

- Horizontally suspended drum by two axles.

- Outer casing in grey skinplate, top panel in stainless steel.

- Vat and drum in AISI 304 stainless steel.

- ET2 control, 7” color touch screen on dirty side.

- Danube Online communication:

- free and easy connection to IoT.

- 2 water inlets.

- 8 signals for dosing pumps, ready to be connected to dosing pumps.

- Central drain valve.

- Automatic positioning of drum.

Barrier Washer

Capacity :35 kgs

- Pass through barrier washer extractors, soft mounted,

- G factor 350, extraction speed 1000 RPM.

- Easy installation, no need for anchoring.

- Horizontally suspended drum by two axles.

- Outer casing in grey skinplate, top panel in stainless steel.

- Vat and drum in AISI 304 stainless steel.

- ET2 control, 7” color touch screen on dirty side.

- Danube Online communication:

- free and easy connection to IoT.

- 2 water inlets.

- 8 signals for dosing pumps, ready to be connected to dosing pumps.

- Central drain valve.

- Automatic positioning of drum.

Barrier Washer

Capacity : 70 kgs( 2 Pockets)

- Pass through barrier washer extractors, soft mounted,

- G factor 350, extraction speed 1000 RPM.

- Easy installation, no need for anchoring.

- Horizontally suspended drum by two axles.

- Outer casing in grey skinplate, top panel in stainless steel.

- Vat and drum in AISI 304 stainless steel.

- ET2 control, 7” color touch screen on dirty side.

- Danube Online communication:

- free and easy connection to IoT.

- 2 water inlets.

- 8 signals for dosing pumps, ready to be connected to dosing pumps.

- Central drain valve.

- Automatic positioning of drum.

Barrier Washer

Capacity : 100 kgs

- Pass through barrier washer extractors, soft mounted,

- G factor 350, extraction speed 1000 RPM.

- Easy installation, no need for anchoring.

- Horizontally suspended drum by two axles.

- Outer casing in grey skinplate, top panel in stainless steel.

- Vat and drum in AISI 304 stainless steel.

- ET2 control, 7” color touch screen on dirty side.

- Danube Online communication:

- free and easy connection to IoT.

- 2 water inlets.

- 8 signals for dosing pumps, ready to be connected to dosing pumps.

- Central drain valve.

- Automatic positioning of drum.

AUTOMATIC DOSING PUMPS

- We present a set of dosing pumps for all professional and industrial ranges of Danube washer extractors. It consists of an initial kit of two pumps with the guide support suitable for up to four pumps. And extra dosage pumps.

Advantages

- We ensure the flow of chemical product over time.

- Detergent saving: cost control.

- More quality in the washing process and in the garments.

- Process homogeneity.

- Freedom and total control of the dosing phase, as it is programmed.

Why our dosing pumps?

- No maintenance

- Easy installation

- Reduced size

- Indicative led when in service.

- Modularity: two-pump starter kit with

- support suitable for up to four pumps.

- Ideal for many sectors and businesses:

- VENDED LAUNDRIES

- SMALL BUSINESSES WITH FEW CYCLES

- SMALL HOTELS

- SCHOOLS, NURSING HOMES.

- CAMPING SITES

AQUABAC water tanks

DANUBE washer extractors, with ET2 and double drain, can be connectedto the AQUABAC water recovery tanks, which allow water recovery, achieving important water and energy savings.

HOW MUCH WATERDOES A WASHER CONSUME ?

A WED-35C high spin washer can consume 875 m3 of water,in operation 10 h a day, 250 days a yearWith different combinations of water tanks, you can save up to 70 % of water with the water recovery AQUABAC. So a water consumption reduced to 262,5 m3.3 Models to recover water, composed of 1, 2 or 3 tanks. External panels in grey skinplate. For WED/WEN 11/14/18/22 kg front washers and MED-16/22 kg ET2 barrier models – 80 lts tanks For WED/WEN 27/35/45 kg front washers and DBW-27/35 kg ET2 barrier models – 150 lts tanks. The tanks are filled with water by means of water valves. Plug and play installation and to connect to Danube ET2 washers. Capacity to recover up to 70% of water. Tanks made of high density polyethylene and removable for easy maintenance and cleaning. Each recoverer has a water intake, fumes exhaust, water outlet and an overflow/drain. Two level sensors (min and max) in each tank. Little space required.